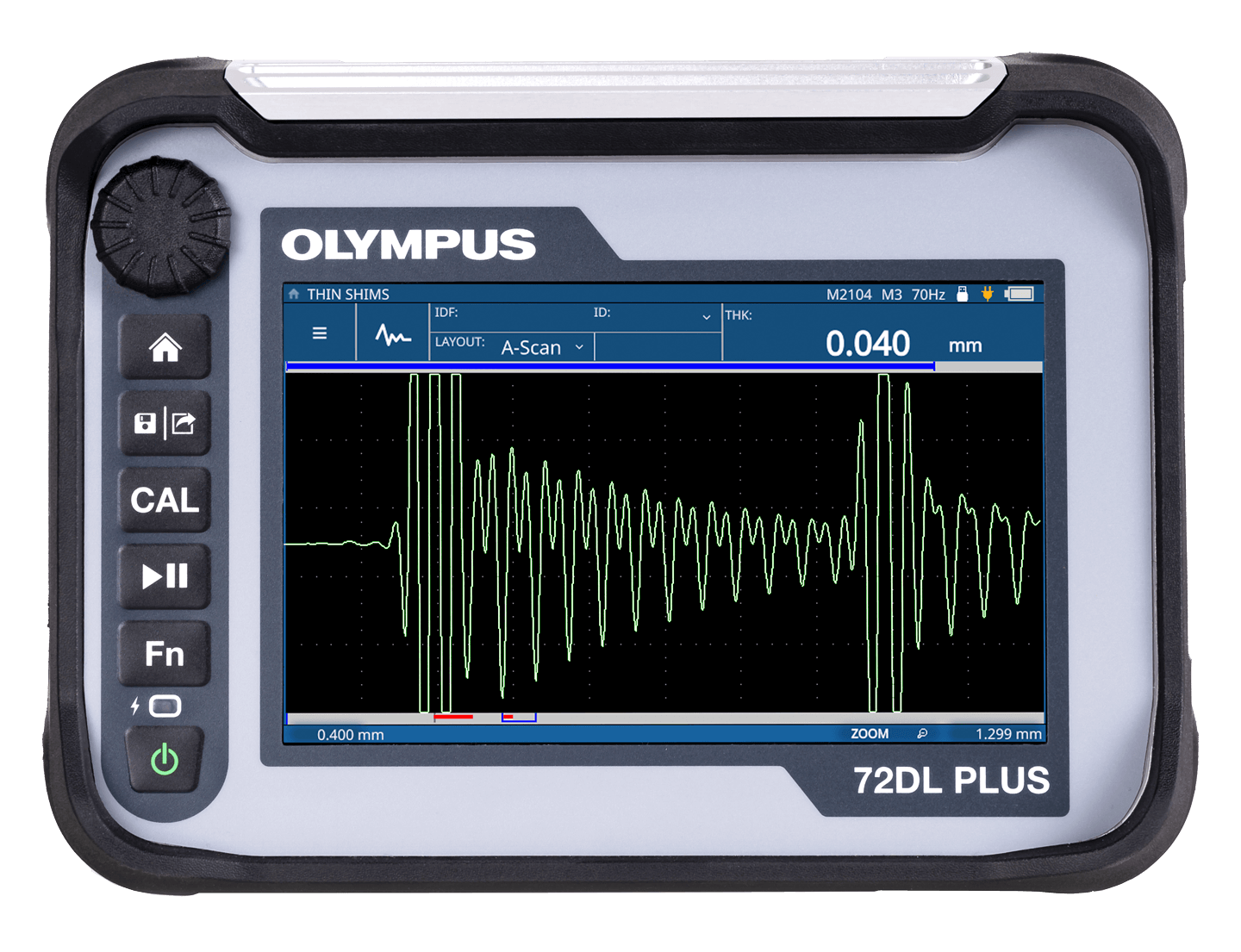

72DL PLUS

72DL PLUS Ultrasonic Thickness Gauge

72DL PLUS™ Ultrasonic Thickness Gauge

High-Speed, High-Frequency, High-Precision Measurements

The Olympus 72DL PLUS™ ultrasonic thickness gauge delivers precision thickness measurements at high speed in a portable, easy-to-use device. With fast scanning, advanced algorithms, and our lowest-ever minimum thickness capability, you can confidently measure the thickness of very thin layers in the most challenging applications.

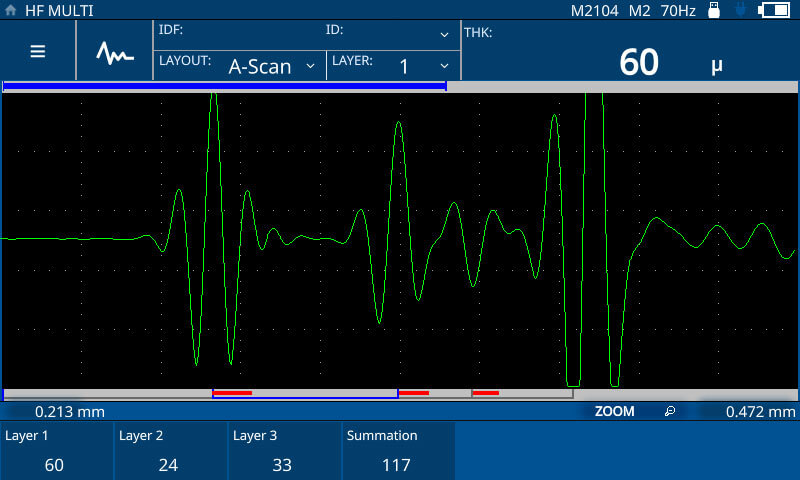

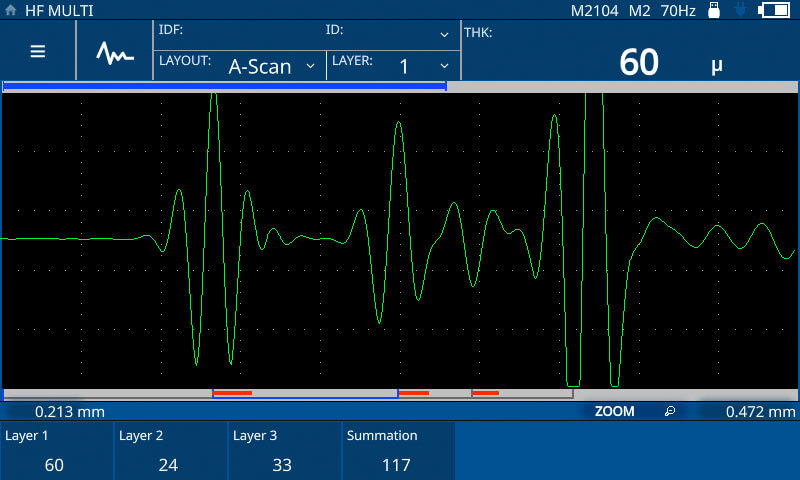

72DL PLUS thickness gauges are available in Standard Frequency and High-Frequency models. The High-Frequency model can measure ultra-thin materials, including multilayer paint, plastics, metals, and coatings, and the Multilayer Measurement Software can simultaneously display the thickness of up to six independent layers. All 72DL PLUS models have the features to perform fast, accurate thickness measurements:

Digital filters enable an excellent signal-to-noise ratio to accurately measure noisy materials (e.g., fiberglass)

High-resolution touch screen is easy to use and see from various angles

PC Interface Application integrates your workflow, inspection management, alerts, and data analysis

72DL PLUS Features at a Glance

Rugged: designed for IP65

Large, clear screen: 177.8 mm (7 in.) high-resolution touch screen WVGA display

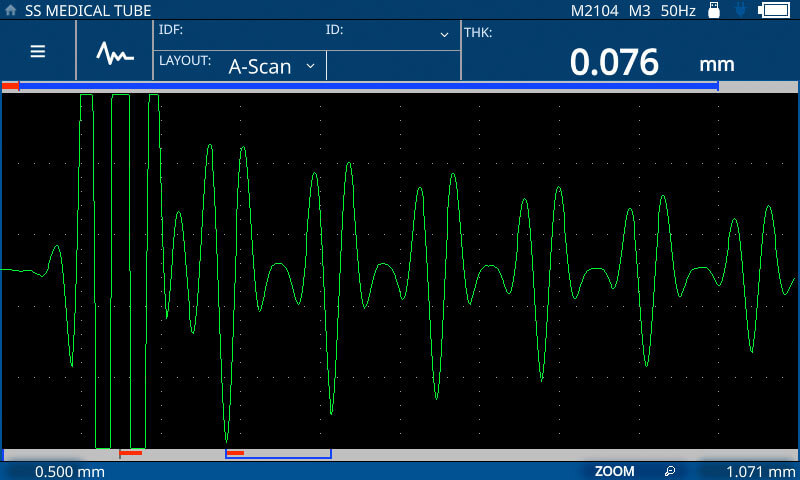

Versatile layouts: A-Scan, B-Scan, A/B-Scan, Trend, and Zoom measurement layouts provide an accurate picture of thickness changes

Customizable: Standard Frequency model and High-Frequency model—with or without the Multilayer Measurement Software option

Long battery life: up to 8 continuous hours

Efficient data management: internal data logging and PC Interface Application speed up data collection and review

Connected: supports wireless LAN and Bluetooth®

Cloud enabled: wireless connection to the Olympus Scientific Cloud™ (OSC) and compatible OSC apps

Easy application setup: create custom applications to reduce device setup time for routine inspections

Intuitive User Interface with an Easy-to-View, Large Screen

Wide viewing angle for outstanding visibility in most ambient conditions

177.8 mm (7 in.), full color touch screen provides access to the setup and measurement layouts

Guided configuration makes it easy to change the settings based on your needs

An Ultrasonic Thickness Gauge Built for Industrial Environments

Designed for IP65 to protect against dust and moisture

Drop tested (MIL-STD-810G) to protect against falls and reduce the need for costly repairs

Takes reliable measurements in a wide operating temperature range of –10°C to 50°C (14°F to 122°F)

Portable for the production floor, weighing 2.1 kg (4.6 lb)

Easy to control from the touch screen, key controls, and adjustment knob

Can be used indoors and outdoors, on a work surface, or using a four-point chest harness or shoulder strap

Measure the Thickness of Up to Six Layers for Multilayer Coatings, Paint, Plastics, and Other Materials

The Multilayer Measurement Software offers multilayer thickness measurements of up to six layers. Measurement settings for each layer—including material, velocity, target thickness ranges, and alarm thresholds—are easily accessible through the configuration workflow and touch-screen controls.

Fast Precision Thickness Gauging for Many Applications

The 72DL PLUS™ instrument can be used as a paint thickness gauge, coating thickness gauge, or material thickness gauge. No matter the application, the gauge delivers reliable, lab-quality measurements at high speed to maximize productivity and throughput on the production floor.

Automotive

Paint thickness gauge for cars and other vehicles

Accurate automotive paint thickness measurements

Measure up to 6 paint layers

Simultaneously display all paint layer measurements at once

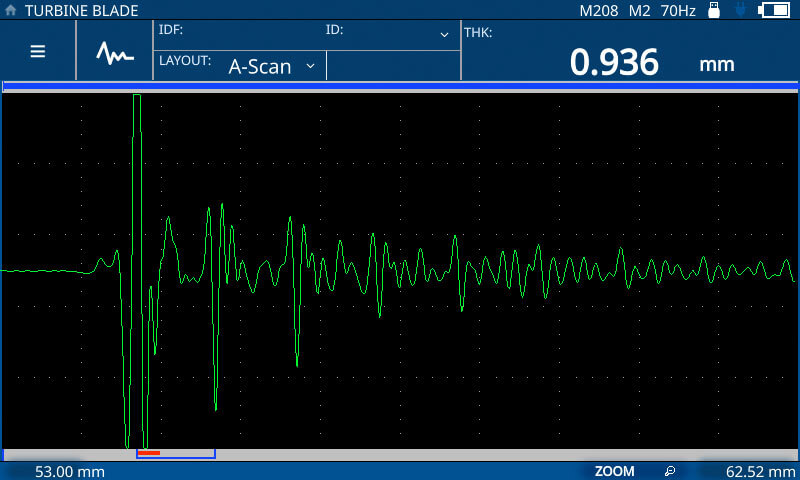

Aerospace

Fast measurements for turbine blade manufacturing

Turbine blade inspection and repair

Aircraft window inspection

Aerospace paint and coatings

Single and multilayer coating material thickness on composite aircraft

Measure coatings on composite aircraft radomes

Aluminum composite panel measurement

General Manufacturing

Measure thin-walled and small-diameter tubing

Plastic and metal tubing

Medical tubing and catheter wall thickness

Coating thickness gauge for manufacturing

Single and multilayer coating material thickness measurements

Waterproof and antireflective coatings

Dry film thickness

Thick and thin film thickness measurements

Plastic thickness gauge for manufacturing

Multilayer plastic thickness measurement of bottles, trays, and tanks

Multilayer plastic food containers

Material thickness gauge for manufacturing

Multilayer material measurements

Silicon wafer thickness

Metal sheet and plate thickness

Gold foil thickness

Adhesive tape thickness

Polypropylene packaging thickness

72DL PLUS™ Specifications

| Standard Frequency | High Frequency | |

| Overall Dimensions (W × H × D) | 238.76 × 172.72 × 86.36 mm (9.4 × 6.8 × 3.4 in.) | |

| Weight | 2.08 kg (4.6 lb) | |

| Power Supply | AC/DC adaptor 24 V, or lithium-ion battery 73 Wh | |

| Battery Life | 8 hrs | |

| Battery Storage Temperature | -20°C to 40°C (-4°F to 104°F) | |

| Operating Temperature | -10°C to 50°C (14°F to 122°F) | |

| Display | 177.8 mm (7 in.) WVGA (800 × 480) PCAP touch, refresh rate 60 Hz | |

| Resolution | LOW: 0.1 mm (0.01 in.) | LOW: 25 μm (1 mil=0.001 in.) |

| STD: 0.01 mm (0.001 in.) | STD: 2.5 μm (0.1 mil=.0.0001 in.) | |

| HI: 0.001 mm (0.0001 in.) | HI: 0.25 μm (0.01 mil=0.00001 in.) | |

| Thickness Range (dependent on probe frequency, probe type, and material) | Steel 0.20 mm to 635 mm (0.0008–25 in.) | Plastic 0.0127 mm to 25.4 mm (0.0005 in - 1 in) |

| Multilayer Measurements | Up to 6 layers | |

| Measurement Rates | 1–3 layers 2 kHz max | 1–3 layers 1 kHz max |

| 4–6 layers 1 kHz max | 4–6 layers 500 Hz max | |

| Calibration | Single- or two-point automatic calibration; zero offset and/or velocity manual adjustment; single-point calibration from frozen waveform | |

| Display Layouts | A-Scan, B-Scan, A/B-Scan, Trend, and Zoom | |

| Capacity | 2 GB; ~400,000 thickness readings, 20,000 waveforms | |

| Frequency Range | 0.2–30 MHz (-3 dB) | 20–125 MHz (-3 dB) |

| Gain | Automatic or Manual (max 100 dB) | Automatic or Manual (max 80 dB) |

| IP Rating | Designed and tested for IP65: protected against dust and water jets from all directions | |

| Explosive Atmosphere | MIL-STD-810F, Method 511.4, Procedure I | |

| Shock Tested | MIL-STD-810F, Method 516.5, Procedure I, 6 cycles each axis, 15 g, 11 ms half sine | |

| Vibration Tested | MIL-STD-810F, Method 514.5, Procedure I, Annex C, Figure 6, general exposure: 1 hour each axis | |