45MG

45MG advanced and reliable ultrasonic thisckness gauge

Overview

45MG Ultrasonic Thickness Gage: |  |

The 45MG is an advanced ultrasonic thickness gage packed with standard measurement features and software options. This unique instrument is compatible with the complete range of Olympus dual element and single element thickness gage transducers, making this innovative instrument an all-in-one solution for virtually every thickness gage application.

Corrosion Measurements with Dual Element Transducers

Precision Measurements with Single Element Transducers

Standard FeaturesIn its basic configuration the 45MG is a simple and straightforward gage that requires minimal operator training to tackle most common thickness gaging applications. With additional optional software options and transducers however, the 45MG can become significantly more advanced and take on applications well beyond that of a typical entry-level gage. Furthermore, most options are available individually at the time of purchase or can be added in the future as your needs change.

| Optional FeaturesFrom a simple corrosion gage to a multi-purpose precision thickness gage with only a few key strokes. The 45MG offers five code-activated software options that makes it one of the most versatile thickness gages in the industry.

|

Built for Tough Environments

|  Indoor display setting, optional A-scan mode |

Designed for Easy Operation

|  Outdoor display setting, optional A-scan mode |

Specifications

| Measurements > Dual element transducer measurement mode | Time interval from a precision delay after the excitation pulse to the first echo |

|---|---|

| Measurements > Echo-to-Echo (optional) | Time interval between two successive back-wall echoes to eliminate paint or coating thickness |

| Measurements > THRU-COAT® measurement (optional) | Measurement of true metal and coating thicknesses with a single back-wall echo (with D7906-SM, D7906-RM, and D7908 transducers) |

| Measurements > Single element transducer measurement modes (optional) | Mode 1: Time interval between the excitation pulse and the first back-wall echo Mode 2: Time interval between the delay line echo and the first back-wall echo (with delay or immersion transducers) Mode 3: Time interval between successive back-wall echoes following the first interface echo after the excitation pulse (with delay line or immersion transducers) |

| Measurements > Thickness range | 0.080 mm to 635 mm (0.003 in. to 25.0 in.) depending on material, transducer, surface conditions temperature, and selected configuration (Full range requires single element option) |

| Measurements > Material velocity range | 0.508 mm/μs to18.699 mm/μs (0.020 in./μs to 0.7362 in./μs) |

| Measurements > Resolution (selectable) | Low: 0.1 mm (0.01 in.) Standard: 0.01 mm (0.001 in.) Single Element option: 0.001 mm (0.0001 in.) |

| Measurements > Transducer frequency range | Standard: 2.25 MHz to 30 MHz (-3 dB) High Penetration (Single Element option): 0.50 MHz to 30 MHz (-3 dB) |

| General > Operating temperature range | -10 °C to 50 °C (14 °F to 122 °F) |

| General > Keypad | Sealed, color-coded keypad with tactile and audible feedback |

| General > Case | Impact-resistant and water-resistant, gasketed case with sealed connectors. Designed for IP67. |

| General > Dimensions (W x H x D) | Overall: 91.1 mm x 162 mm x 41.1 mm (3.59 in. x 6.38 in. x 1.62 in) |

| General > Weight | 430.9 g (0.95 lb) |

| General > Power Supply | 3 AA batteries/USB power supply |

| General > Battery life operating time | 3 AA alkaline: 20 to 21 hours 3 AA NiMH: 22 to 23 hours AA Lithium: 35 to 36 hours |

| General > Standards | Designed for EN15317 |

| Display > Color transflective QVGA display | Liquid crystal display, display area 54.61 mm x 41.15 mm (2.15 in. x 1.62 in.) |

| Display > Rectification | Full wave, RF, half-wave positive, or half-wave negative (Waveform option) |

| Inputs/Outputs > USB | 2.0 client |

| Inputs/Outputs > Memory card | Maximum capacity: 2 GB removable microSD memory card |

| Internal Data Logger (Optional) > Data logger | The 45MG identifies, stores, recalls, clears, and transmits thickness readings, waveform images, and gage configuration information through USB or microSD. |

| Internal Data Logger (Optional) > Capacity | 475,000 thickness measurements or 20,000 waveforms with thickness measurements |

| Internal Data Logger (Optional) > File names, IDs, and comments | 32-character file names and 20-character alphanumeric location codes with four comments per location |

| Internal Data Logger (Optional) > File structure | Six standard or custom application-specific file structures |

| Internal Data Logger (Optional) > Reports | On-gage reporting of summary with statistics, Min./Max. |

Standard Package

- 45MG digital ultrasonic thickness gage

- AA alkaline batteries

- 2-step test block and couplant

- USB cable

- User's manual on CD

- Measurement features: Min./Max. mode, two alarm modes, Differential, mode, B-scan, Reduction Rate, Programmable Lock

Software Options

- 45MG-SE (U8147022): Single Element option to use single element transducers with frequency range of 2.25 MHz to 30 MHz.

- 45MG-HP (U8147023): Single Element High Penetration option to use single element transducers with frequency range of 0.5 MHz to 30 MHz.

- 45MG-EETC (U8147021): Echo-to-Echo and THRU-COAT®

- 45MG-WF (U8147019): Waveform option

- 45MG-DL(U8147020): Internal data logger including GageView interface program

Optional Accessories

- MICROSSD-ADP-2GB (U8779307): 2 GB External microSD memory card

- 45MG-RPC (U8779676): Rubber protective boot with stand

Software Options

The 45MG offers five code-activated software options that makes it one of the most versatile thickness gages in the industry.

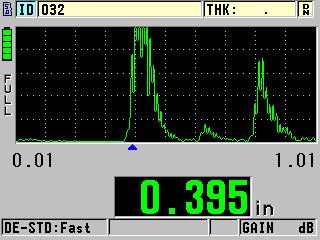

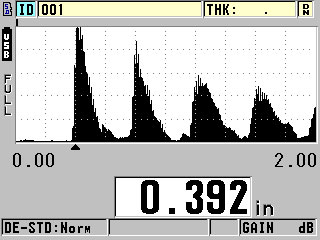

Echo-to-Echo / THRU-COAT® Option

Echo-to-Echo The gage displays the true metal thickness and ignores the thickness of the coating layer, using multiple back-wall echoes:

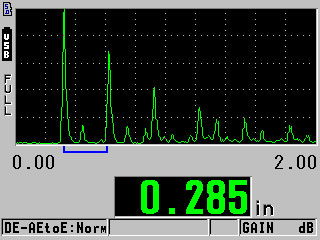

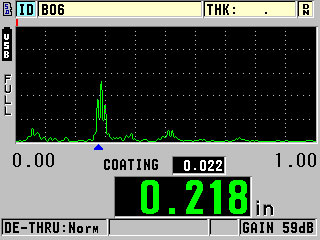

| THRU-COAT Technology

|

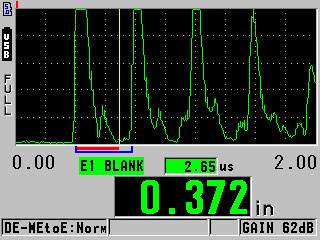

Auto Echo-to-Echo mode with A-scan |  THRU-COAT mode showing thickness of coating and steel (waveform not activated) |

Manual Echo-to-Echo adjusting the First Echo blank |  THRU-COAT mode with optional waveform |

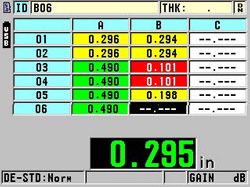

Single Element Software Option

The Single Element software option enables you to make very precise thickness measurements at a resolution of up to 0.0001 in. or 0.001 mm. Compatible with single element Microscan transducers ranging from 2.25 MHz to 30 MHz.

- Most materials, from thin to thick

- Plastic bottles, tubes, pipes, sheets as thin as 0.08 mm (0.003 in.)

- Metal containers, steel coils, machined parts as thin as 0.10 mm (0.004 in.)

- Cylinder bores, turbine blades

- Glass bulbs, bottles

- Thin fiberglass, rubber, ceramics, and composite materials

- Curved areas or containers with small radii

Single Element High Penetration Software Option

This option allows you to use low frequency single element transducers (as low as 0.5 MHz) to measure thick or highly attenuating materials such as rubber, fiberglass, castings, and composites. Included is the Single Element option.

- Most thick or sound-attenuating materials

- Thick cast metal parts

- Thick rubber tires, belts

- Fiberglass boat hulls, storage tanks

- Composite panels

- Resolution of 0.01 mm (0.001 in.) for transducer frequencies of 0.5 MHz and 1.0 MHz

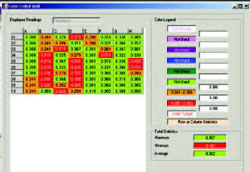

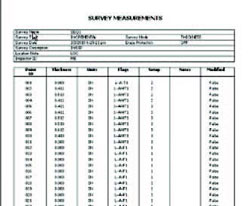

Optional Data Logger and PC Interface

The 45MG has a full-featured internal bidirectional alphanumeric data logger that is designed to easily store and transfer thickness readings and waveform data. The data logger option includes the GageView™ Interface program. Data Logger Option

|

GageViewInterface Program

|

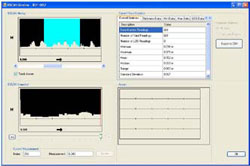

Live A-Scan With Waveform Adjust

This optional Live A-scan mode allows users to view the ultrasound waveform (or A-scan) directly on the gage's display, verify the thickness measurement, and make manual adjustments to gain and blanking settings to maximize measurement performance in challenging applications. This helpful option features Manual Gain Adjust, Extended Blanking, First Echo Blank, Range, and Delay.

Transducers

Transducers for Precision Thickness Gages | Transducers for Corrosion Thickness Gages |

Olympus NDT offers a complete selection of transducers, cables, couplants, calibration test blocks, and accessories to meet a wide variety of ultrasonic precision thickness gaging applications.